CNC LATHE MACHINE INFORMATION

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

-

07-20-2012, 09:13 AM #1

Plastic

Plastic

- Join Date

- Dec 2011

- Location

- Georgia, USA

- Posts

- 4

Bench Top CNC Lathe Opinions

Bench Top CNC Lathe Opinions

My company is new to turning and is trying to get a few bench top CNC lathes to do some small ceramic piece turning with. So my question is this: anybody got any manufacturers they have particularly liked? Particularly hated? Why? Any general advice?

For further background, in our attempts to be economical we now have a MircoKinetics lathe that we have not been very satisfied with. I have read/heard to avoid lathes assembled from Chinese parts, which are typically of lower quality, but obviously more competitively priced. Currently looking into Optimum and MDA precision, but would like some experienced input and more choices. Any opinion on Mach3 control software? Thanks tons for any advice. -

07-20-2012, 03:06 PM #2

Cast Iron

Cast Iron

- Join Date

- Oct 2010

- Location

- Dewees Texas

- Posts

- 270

We are using Omini Turns on a Tsugami Chucker and one on a Hardinge AHC. Between the 2 machines they have run about 30 years trouble free.

Programing is relatively easy (Different from real CNCs)

#1 Does not have a tail stock.

#2 Fairly compact but not really portable if you need to carry them up stairs

#3 Good precision

Dyna Mectronics made mills that could be considered bench top, I do not know if they still make lathes and if they or any good or would be bench top -

07-22-2012, 03:44 PM #3

Plastic

Plastic

- Join Date

- May 2012

- Location

- Helsinki, Finland

- Posts

- 14

Mach3 is very intuitive and easy to use. However, it kept losing zero at random intervals on a mini-mill I used. I don't know if it was a quirk in the machine or the software.

Also, if your Mach3 never seems to get G2 and G3 right... try putting a G91.1 at the beginning of every program you write. It has something to do with how the control fetches the zero point for a circle. Use G90 and G91 normally in addition. -

07-22-2012, 04:38 PM #4

Plastic

Plastic

- Join Date

- Apr 2010

- Location

- Wales

- Posts

- 13

Hi everyone, i have converted many Denford and Boxford desktop mills and lathes to Mach3, they're not production machines but on small runs they cope well.

I've never had any problems with zeros or G2 G3 moves with mach, but some people have had problems with control issues on the computer from other software installed. I always set my computers up with XP and Mach3 and nothing else.

You may find find them a bit thin on the ground in the USA. -

07-22-2012, 05:24 PM #5

Titanium

Titanium

- Join Date

- Sep 2002

- Location

- Lawrenceville GA USA

- Posts

- 3,593

For your application I believe you will find the Omni Turn machines desirable as they are easy to repair and ceramic dust tends to damage machine parts over time. There are several shops locally running them and they have a pretty good reputation. They are not benchtop machines but they are small and accurate and pretty cost effective.

I can understand if you are not happy with the MicroKenetics machines, they have always been tough to work with.

Charles -

07-23-2012, 04:47 AM #6

Stainless

Stainless

- Join Date

- Oct 2006

- Location

- Boston,Mass.

- Posts

- 1,634

Tormach will be releasing a new lathe in 6-12 month...prototypes are made and testing is being done...

-

07-23-2012, 05:12 AM #7

Stainless

Stainless

- Join Date

- Feb 2004

- Location

- Staten Island NewYork USA

- Posts

- 1,744

I looked very seriously at the Omniturns...I never heard a bad thing about them...for what they are. Good, robust, accurate machines but somewhat limited for certain production and fell short where I needed...so went with a larger CNC that was more versatile.

Small lathe...you may want to look at the Haas Office lathe. I have a few customers that love theirs...I looked into one very quickly, just not enough machine for my application..but given the right circumstances it could have been a real asset for very little space. -

07-23-2012, 11:35 AM #8

-

07-24-2012, 07:08 AM #9

Stainless

Stainless

- Join Date

- Sep 2006

- Location

- Atlanta, GA

- Posts

- 1,214

Why the big need for a turret? I have a Mazak QT-8 and a Hardinge DV 59 with a CNC gang tool attachment and for small parts 1" and less the Hardinge will run circles around the Mazak in regard to cycle time. Its just a matter of marring up the right parts to the right machine.

There are used Omni turns and Hardinges that pop up on EBay from time to time ~10k or less for some pretty decent machines. If I had it to do over again I would go with the Omni control over a Fagor control any day. -

07-24-2012, 08:49 AM #10

Simple really. For me, it's more about your last sentence. The types of parts we do are better suited to a turret than a gang.

And cycle times don't really mean squat for us because it's all prototyping. I'll likely never make another widget like the widget I just made. -

07-24-2012, 10:28 AM #11

Haas sold the gt-20 with a turret like this one:

1 Haas HAAS CNC CONTROL, Max. 4000 rpm, Haas GT20, , CNC LATHES - Machine Tools - Second hand machinery - Wotol.com

My old shop teacher just got one in for the shop, he seems to like it. Its a nice sized smaller lathe.

Jason,

Not to be confused with Turing.

This article is about the machining operation. For the generic use of the word, see rotating.

| This article needs additional citations for verification. (January 2010) |

Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other types of machining besides turning.)

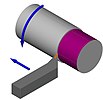

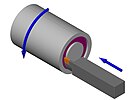

When turning, a piece of relatively rigid material (such as wood, metal, plastic, or stone) is rotated and a cutting tool is traversed along 1, 2, or 3 axes of motion to produce precise diameters and depths. Turning can be either on the outside of the cylinder or on the inside (also known as boring) to produce tubular components to various geometries. Although now quite rare, early lathes could even be used to produce complex geometric figures, even the platonic solids; although since the advent of CNC it has become unusual to use non-computerized toolpath control for this purpose.

The turning processes are typically carried out on a lathe, considered to be the oldest machine tools, and can be of four different types such as straight turning, taper turning, profiling or external grooving. Those types of turning processes can produce various shapes of materials such as straight, conical, curved, or grooved workpiece. In general, turning uses simple single-point cutting tools. Each group of workpiece materials has an optimum set of tools angles which have been developed through the years.

The bits of waste metal from turning operations are known as chips (North America), or swarf (Britain). In some areas they may be known as turnings.

Contents |

Turning operations

Turning specific operations include:- Turning

-

- Tapered turning

- a) from the compound slide b) from taper turning attachment c) using a hydraulic copy attachment d) using a C.N.C. lathe e) using a form tool f) by the offsetting of the tailstock - this method more suited for shallow tapers.[2]

-

- Spherical generation

- The proper expression for making or turning a shape is to generate as in to generate a form around a fixed axis of revolution. a) using hydraulic copy attachment b) C.N.C. (computerised numerically controlled) lathe c) using a form tool (a rough and ready method) d) using bed jig (need drawing to explain).[2]

-

- Hard turning

- Hard turning is a turning done on materials with a Rockwell C hardness greater than 45. It is typically performed after the workpiece is heat treated.[3]

-

- The process is intended to replace or limit traditional grinding operations. Hard turning, when applied for purely stock removal purposes, competes favorably with rough grinding. However, when it is applied for finishing where form and dimension are critical, grinding is superior. Grinding produces higher dimensional accuracy of roundness and cylindricity. In addition, polished surface finishes of Rz=0.3-0.8z cannot be achieved with hard turning alone. Hard turning is appropriate for parts requiring roundness accuracy of 0.5-12 micrometres, and/or surface roughness of Rz 0.8–7.0 micrometres. It is used for gears, injection pump components, hydraulic components, among other applications.[3]

- Facing

- is part of the turning process. It involves moving the cutting tool at right angles to the axis of rotation of the rotating workpiece.[1] This can be performed by the operation of the cross-slide, if one is fitted, as distinct from the longitudinal feed (turning). It is frequently the first operation performed in the production of the workpiece, and often the last- hence the phrase "ending up".

- Parting

This process is used to create deep grooves which will remove a completed or part-complete component from its parent stock.

This process is used to create deep grooves which will remove a completed or part-complete component from its parent stock.- Grooving

- Boring

- Enlarging or smoothing an existing hole created by drilling, moulding etc.i.e. the machining of internal cylindrical forms (generating) a) by mounting workpiece to the spindle via a chuck or faceplate b) by mounting workpiece onto the cross slide and placing cutting tool into the chuck. This work is suitable for castings that are to awkward to mount in the face plate. On long bed lathes large workpiece can be bolted to a fixture on the bed and a shaft passed between two lugs on the workpiece and these lugs can be bored out to size. A limited application but one that is available to the skilled turner/machinist.[2]

- Drilling

- is used to remove material from the inside of a workpiece. This process utilizes standard drill bits held stationary in the tail stock or tool turret of the lathe.

- Knurling

- The cutting of a serrated pattern onto the surface of a part to use as a hand grip using a special purpose knurling tool.[2]

- Threading

- Both standard and non-standard screw threads can be turned on a lathe using an appropriate cutting tool. (Usually having a 60, or 55° nose angle) Either externally, or within a bore.[4] Generally referred to as single-point threading.

- tapping of threaded nuts and holes a) using hand taps and tailstock centre b)using a tapping device with a slipping clutch to reduce risk of breakage of the tap.[2]

- threading operations include a)all types of external and internal thread forms using a single point tool also taper threads, double start threads, multi start threads, worms as used in worm wheel reduction boxes, leadscrew with single or multistart threads. b) by the use of threading boxes fitted with 4 form tools, up to 2" diameter threads but it is possible to find larger boxes than this.[2]

Lathes

Main article: Lathe

A lathe is a machine tool used principally for shaping pieces of

metal, wood, or other materials by causing the workpiece to be held and

rotated by the lathe while a tool bit is advanced into the work causing

the cutting action. Lathes can be divided into three types for easy

identification: engine lathe, turret lathe, and special purpose lathes.

Some smaller ones are bench mounted and semi-portable. The larger

lathes are floor mounted and may require special transportation if they

must be moved. Field and maintenance shops generally use a lathe that

can be adapted to many operations and that is not too large to be moved

from one work site to another. The engine lathe is ideally suited for

this purpose. A trained operator can accomplish more machining jobs with

the engine lathe than with any other machine tool. Turret lathes and

special purpose lathes are usually used in production or job shops for mass production or specialized parts, while basic engine lathes are usually used for any type of lathe work.Workholding methods

- Chuck: Chucks are a very common workholding method. There are many types, some for round and square stock, and other for irregular shapes.

- Collet: Primarily used for small round workpieces.

- Faceplate: A faceplate, drive dog, and mandrel may be used to turn workpieces such as gear blanks.

- Drive center: Use hydraulic or spring-loaded teeth that "bite" into the end of workpieces and can be used when the entire length of the workpiece must be machined.

Tooling

Main article: Tool bit

The various angles, shapes, and sizes of a single-point cutting tool have direct relation to the resulting surface of a workpiece in machining operations. Different types of angle such as rake angle, side rake angle, cutting-edge angle, relief angle, nose radius exist and may be different with respect to the workpiece. Also, there are many shapes of single-point cutting tools, such as V-shaped and Square. Usually, a special toolholder is used to hold the cutting tool firmly during operation.Dynamics of turning

Forces

The relative forces in a turning operation are important in the design of machine tools. The machine tool and its components must be able to withstand these forces without causing significant deflections, vibrations, or chatter during the operation. There are three principal forces during a turning process:- The cutting or tangential force acts downward on the tool tip allowing deflection of the workpiece upward. It supplies the energy required for the cutting operation.

- The axial or feed force acts in the longitudinal direction. It is also called the feed force because it is in the feed direction of the tool. This force tends to push the tool away from the chuck.

- The radial or thrust force acts in the radial direction and tends to push the tool away from the workpiece.

Speeds and feeds

Speeds and feeds for turning are chosen based on cutter material, workpiece material, setup rigidity, machine tool rigidity and spindle power, coolant choice, and other factors.See also

References

- ^ a b Todd, Robert H.; Allen, Dell K.; Al ting, Leo (1994), Manufacturing Processes Reference Guide, p. 153, ISBN 0-8311-3049-0.

- ^ a b c d e f g Workshop Technology by W.A.J. Chapman Ph.D. M.Sc.(Eng.), M.I.Mech.E., M.I.Prod.E. Principal Hatfield College of Technology, Hertfordshire first published 1951 part one, two and three published by Edward Arnold (publishers Limited

- ^ a b Koepfer, Chris, "Hard Turning as an Alternative to Grinding", Production Machining, 1/22/2010. productionmachining.com, accessed 3/4/2010

- ^ "Threading On A Lathe : Modern Machine Shop". Mmsonline.com. 2003-01-15. Retrieved 2012-03-13.

External links

- "Lathe Introduction". Archived from the original on 2010-01-08. Retrieved 2010-01-08.

- Schneider, George. "Turning Tools and Operations." American Machinist, January, 2010.

Machine

Honge Precision Industies Corp. : CNC Drilling Machine

( Origin : Taiwan Manufacturers & Suppliers )

Honge Precision Industies Corp. was established in 2004. Our main products including CNC Drilling Machine, deep hole Drilling Machine, gundrilling Machine, and honing Machine.

Our products have been exporter to the Mainland China, Europe, Japan

and most Asian countries. Due to our excellent quality, good management

system and superior after-sales service, we have already enjoyed a

long-lasting good reputation in the world market. We also constantly

spend a lot of money on R&D to develop new, multi-functional and

advanced products in order to growing steady. Honge is honor to accept

your suggestion and support.

Honge Precision Industies Corp. was established in 2004. Our main products including CNC Drilling Machine, deep hole Drilling Machine, gundrilling Machine, and honing Machine.

Our products have been exporter to the Mainland China, Europe, Japan

and most Asian countries. Due to our excellent quality, good management

system and superior after-sales service, we have already enjoyed a

long-lasting good reputation in the world market. We also constantly

spend a lot of money on R&D to develop new, multi-functional and

advanced products in order to growing steady. Honge is honor to accept

your suggestion and support.

- Also see products: CNC Drilling Machine or its product categories

Benign Enterprise Co. Ltd. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier ) Taiwan Drilling Machinery manufacturer, Benign Enterprise Co. Ltd. specializes in manufacturing high-quality Drilling Machines.

We always supply first-class products and services for our customers.

Benign is innovative to produce high quality products with perfect

appearances, highly effective, energy and Powder saving, low noise, low

wastage and fully automatic characteristics. Furthermore, we have

obtained good comments from all our clients. You are warmly welcome to

contact us and build long-term and mutually beneficial business

relationships. We can ensure that you can be satisfied with our high

quality and reliable products.

Taiwan Drilling Machinery manufacturer, Benign Enterprise Co. Ltd. specializes in manufacturing high-quality Drilling Machines.

We always supply first-class products and services for our customers.

Benign is innovative to produce high quality products with perfect

appearances, highly effective, energy and Powder saving, low noise, low

wastage and fully automatic characteristics. Furthermore, we have

obtained good comments from all our clients. You are warmly welcome to

contact us and build long-term and mutually beneficial business

relationships. We can ensure that you can be satisfied with our high

quality and reliable products.

- Also see products: CNC Drilling Machine or its product categories

- Press release: 2011 TIMTOS...

Ares Machinery Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan & Mainland China Manufacturers & Suppliers )

Since it's established, Ares has been committed to constant R&D, continued improvements on quality and functionality of CNC drillings, CNC Drilling Machine, tapping centers, CNC production centers, Machine

tools as well as the development of completely new models. Ares

combines the knowledge of domestic academic institutions with its own

advanced technology, in the pursuit of perfect performance and new

realms of quality. In July of 1994 Ares was founded on the maxim

“Quality as Priority Guarantees Durability, Perpetual Service Ensures

Vitality.” Insisting on maintaining the same standards and quality as

advanced countries, the company was EMC and CE certified in 1996, ISO

9002 certified in January of 1999, and TUV of Germany granted ISO

9001:2000 certification in 2002.

Since it's established, Ares has been committed to constant R&D, continued improvements on quality and functionality of CNC drillings, CNC Drilling Machine, tapping centers, CNC production centers, Machine

tools as well as the development of completely new models. Ares

combines the knowledge of domestic academic institutions with its own

advanced technology, in the pursuit of perfect performance and new

realms of quality. In July of 1994 Ares was founded on the maxim

“Quality as Priority Guarantees Durability, Perpetual Service Ensures

Vitality.” Insisting on maintaining the same standards and quality as

advanced countries, the company was EMC and CE certified in 1996, ISO

9002 certified in January of 1999, and TUV of Germany granted ISO

9001:2000 certification in 2002.

- Also see products: CNC Drilling Machine or its product categories

Ocean Techologies Co., Ltd. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier )

Ocean Technologies Co.,Ltd., was established in 2000. Our company is a professional manufacturer of metal cutting machinery, EDM Drilling Machines, broaching and tapping Machine, Drilling

EDM and automatic control design. Ocean Tech hold honesty as our

principle to server customers for long-term cooperation within

customers, suppliers and crafts. We also hope that we could build up

close partnership for mutual profit. Please refer to (1) NEW NC EDM Drilling Machine (2) New EDM Portable Drilling Machines (3) New ZNC Drilling Machines.

Please feel free to browse through our product category to have

detailed information of sawing machines. Contact us right now!

34

Ocean Technologies Co.,Ltd., was established in 2000. Our company is a professional manufacturer of metal cutting machinery, EDM Drilling Machines, broaching and tapping Machine, Drilling

EDM and automatic control design. Ocean Tech hold honesty as our

principle to server customers for long-term cooperation within

customers, suppliers and crafts. We also hope that we could build up

close partnership for mutual profit. Please refer to (1) NEW NC EDM Drilling Machine (2) New EDM Portable Drilling Machines (3) New ZNC Drilling Machines.

Please feel free to browse through our product category to have

detailed information of sawing machines. Contact us right now!

34

- Also see products: CNC Drilling Machine or its product categories

1. Wen Chih Machinery Industrial Co., Ltd. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier ) Wen Chih Machinery Industrial Co., Ltd. is one of a professional manufacturer of Drilling Machine

and other products. We are keeping on researching, developing, and

innovating the most advanced products and services for our customers,

our trained professional team and qualified products has been doing our

best to reach the unchanged goal of building and remaining the nicest

long-term relationship with our customers. Punctual delivery and top

quality at competitive price are our guarantee. We always keep

innovation, perfect quality, reasonable price and prompt delivery in

mind to meet customers' needs. We also provide many kind of Drilling Machines, welcome to our website to get more information!

Wen Chih Machinery Industrial Co., Ltd. is one of a professional manufacturer of Drilling Machine

and other products. We are keeping on researching, developing, and

innovating the most advanced products and services for our customers,

our trained professional team and qualified products has been doing our

best to reach the unchanged goal of building and remaining the nicest

long-term relationship with our customers. Punctual delivery and top

quality at competitive price are our guarantee. We always keep

innovation, perfect quality, reasonable price and prompt delivery in

mind to meet customers' needs. We also provide many kind of Drilling Machines, welcome to our website to get more information!* Company Link * Company Profile * View All Items

2. Ming Fong Technology Co.,LTD : CNC Drilling Machine

( Origin : Taiwan Manufacturers & Suppliers ) Ming Feng Technology Co.,LTD offer our customers a comprehensive range of CNC Drilling Machine

that match the strict quality requirements of international market

which has earned our company the distinct reputation of being a quality

oriented Taiwan exporter of our products. We are recognized as one of

the leading traders in this sector due to our capability to supply

filling equipment to our customers. We laid our foot years back &

ever since we are striving to deliver in our products innovation,

competitive pricing & quality driven customer satisfaction. We also

provide many kind of products, welcome to our website to get more

information.

Ming Feng Technology Co.,LTD offer our customers a comprehensive range of CNC Drilling Machine

that match the strict quality requirements of international market

which has earned our company the distinct reputation of being a quality

oriented Taiwan exporter of our products. We are recognized as one of

the leading traders in this sector due to our capability to supply

filling equipment to our customers. We laid our foot years back &

ever since we are striving to deliver in our products innovation,

competitive pricing & quality driven customer satisfaction. We also

provide many kind of products, welcome to our website to get more

information.* Company Link * Company Profile * View All Items

3. Tailift Co., Ltd. : CNC Drilling Machines

( Origin : Taiwan & Mainland China Manufacturer & Supplier )

Tailift Co., Ltd. offer our customers a comprehensive range of Drilling Machine

that match the strict quality requirements of International market

which has earned our company the distinct reputation of being a quality

oriented Taiwan Exporter of our products. We are recognized as one of

the leading traders in this sector due to our capability to supply

impeccable Radial Drill Machines

to our customers. We laid our foot years back & ever since we are

striving to deliver in our products innovation, competitive pricing

& quality driven customer satisfaction. We also provide many kind of

products, welcome to our website to get more information!

Tailift Co., Ltd. offer our customers a comprehensive range of Drilling Machine

that match the strict quality requirements of International market

which has earned our company the distinct reputation of being a quality

oriented Taiwan Exporter of our products. We are recognized as one of

the leading traders in this sector due to our capability to supply

impeccable Radial Drill Machines

to our customers. We laid our foot years back & ever since we are

striving to deliver in our products innovation, competitive pricing

& quality driven customer satisfaction. We also provide many kind of

products, welcome to our website to get more information!* Company Link * Company Profile * Company Video * View All Items

4. Taiwan Rong Fu Industrial Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan & Mainland China Manufacturers & Suppliers ) Taiwan Rong Fu manufactures milling/Drilling machines and metal cutting band saws, including 5" metal cutting band saws, CNC Drilling Machine,

dual column automatic metal cutting band saws, fully automatic band

saw, and etc. more than 30 years, for the domestic and overseas markets.

We are rated No.1 in Taiwan in the export of milling/Drilling

and band saws. Our BANDSAW products include horizontal type, European

type, vertical type, semi and fully automatic, and circular saw. The

mill/Drilling machines cover from light duty to heavy duty, also with radial Drilling

machines. Our customers enjoy variety selections and ONE STOP shopping

at our door. At Rong Fu, customers always enjoy efficient and trustable

after sales service, with continuous developing program. Welcome to join

us now!

Taiwan Rong Fu manufactures milling/Drilling machines and metal cutting band saws, including 5" metal cutting band saws, CNC Drilling Machine,

dual column automatic metal cutting band saws, fully automatic band

saw, and etc. more than 30 years, for the domestic and overseas markets.

We are rated No.1 in Taiwan in the export of milling/Drilling

and band saws. Our BANDSAW products include horizontal type, European

type, vertical type, semi and fully automatic, and circular saw. The

mill/Drilling machines cover from light duty to heavy duty, also with radial Drilling

machines. Our customers enjoy variety selections and ONE STOP shopping

at our door. At Rong Fu, customers always enjoy efficient and trustable

after sales service, with continuous developing program. Welcome to join

us now!* Company Link * Company Profile * View All Items

5. Shuz Tung Machinery Industrial Co., Ltd. : CNC Drilling Machines

( Origin : Taiwan & Mainland China Manufacturer & Supplier )

Taiwan Drilling Machine manufacturers, Shuz Tung Machinery Industrial Co., Ltd. specializes in manufacturing high-quality Water Bottle Hole Drilling Machines.

We always supply first-class products and services for our customers.

Shuz Tung is innovative to produce high quality products with perfect

appearances, highly effective, energy and powder saving, low noise, low

wastage and fully automatic characteristics. Furthermore, we have

obtained good comments from all our clients. You are warmly welcome to

contact us and build long-term and mutually beneficial business

relationships. We can ensure that you can be satisfied with our high

quality and reliable products.

Taiwan Drilling Machine manufacturers, Shuz Tung Machinery Industrial Co., Ltd. specializes in manufacturing high-quality Water Bottle Hole Drilling Machines.

We always supply first-class products and services for our customers.

Shuz Tung is innovative to produce high quality products with perfect

appearances, highly effective, energy and powder saving, low noise, low

wastage and fully automatic characteristics. Furthermore, we have

obtained good comments from all our clients. You are warmly welcome to

contact us and build long-term and mutually beneficial business

relationships. We can ensure that you can be satisfied with our high

quality and reliable products.* Company Link * Company Profile * Company Video * View All Items

6. Chin Minn Industries Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan Manufacturers & Suppliers )

Professional manufacturer and exporter of custom-designed roll

forming machinery. Chin Minn Industries Co., Ltd. specialize in roll

forming Machine for ball slide rails and special purpose machines like rotary type Drilling and tapping Machine, CNC Drilling Machine, spindle recessing machines, Drilling and punching machines, honing machines, pneumatic Drilling

machines. Develop new products to meet our customer demands in a

dynamic ever-changing marketplace. Due to our excellent quality, good

management system and superior customer service, we have already enjoyed

a long-lasting good reputation in this field market. It will be your

wisdom selection to cooperate the business with Chin Minn. We sincerely

hope to be your best partner in business. Don't hesitate and contact

with us as soon as you...

Professional manufacturer and exporter of custom-designed roll

forming machinery. Chin Minn Industries Co., Ltd. specialize in roll

forming Machine for ball slide rails and special purpose machines like rotary type Drilling and tapping Machine, CNC Drilling Machine, spindle recessing machines, Drilling and punching machines, honing machines, pneumatic Drilling

machines. Develop new products to meet our customer demands in a

dynamic ever-changing marketplace. Due to our excellent quality, good

management system and superior customer service, we have already enjoyed

a long-lasting good reputation in this field market. It will be your

wisdom selection to cooperate the business with Chin Minn. We sincerely

hope to be your best partner in business. Don't hesitate and contact

with us as soon as you...* Company Link * Company Profile * Company Video * View All Items

7. Kao Fong Machinery Co., Ltd. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier ) Fong Machinery Co., Ltd. was established in 1968. We are one of the manufacturer of CNC Drilling Machine.

We provide our customers with a wide range of the top quality machining

center products. We will thoroughly evaluate and test every products to

ensure the highest quality. Welcome to ask Fong Machinery for more

details. We laid our foot years back & ever since we are striving to

deliver in our products innovation, competitive pricing & quality

driven customer satisfaction. We wish to have a long term business

relationship with you in the near future.

Fong Machinery Co., Ltd. was established in 1968. We are one of the manufacturer of CNC Drilling Machine.

We provide our customers with a wide range of the top quality machining

center products. We will thoroughly evaluate and test every products to

ensure the highest quality. Welcome to ask Fong Machinery for more

details. We laid our foot years back & ever since we are striving to

deliver in our products innovation, competitive pricing & quality

driven customer satisfaction. We wish to have a long term business

relationship with you in the near future.* Company Link * Company Profile * View All Items

8. Top-One Machinery Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan & Mainland China Manufacturers & Suppliers ) Top-One Machinery Co., Ltd. established in 1989 is a Deep Drilling Machine manufacturer. We manufacture top quality of Deep Drilling Machines.

We strive to improve our quality & technology. We offer

high-quality, competitive prices, prompt delivery to our customers. With

these advantages you can develop your market with our machines without

difficulty and we trust we shall be able to fulfill your need. Meanwhile

buyer's designs are welcome and appreciated. If you are in the business

about this field, please contact us for more details. We wish to have a

long term business relationship with you in the near future.

Top-One Machinery Co., Ltd. established in 1989 is a Deep Drilling Machine manufacturer. We manufacture top quality of Deep Drilling Machines.

We strive to improve our quality & technology. We offer

high-quality, competitive prices, prompt delivery to our customers. With

these advantages you can develop your market with our machines without

difficulty and we trust we shall be able to fulfill your need. Meanwhile

buyer's designs are welcome and appreciated. If you are in the business

about this field, please contact us for more details. We wish to have a

long term business relationship with you in the near future.* Company Link * Company Profile * View All Items

9. Tech Plus Precision Machinery Industry Co., Ltd. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier )

Established in 2006, Tech Plus Precision has upheld this

principle as the company’s policies and objectives to research, develop,

and design the Machine. Our main products are high speed glass engraving machines & engraving milling Machine, CNC Drilling Machine,

double column hi-speed machining center, double column integrate

machining center, etc. With its dedicated employees, the company was

awarded CE Certification in 2007 and the Certification of Tool Rest

Structure Design in 2008, the same year it developed the machining

center spindle shift mechanism, and the vacuum device for the processing

Machine was designed in 2009. We firmly believe that the

integrity of management, for all the needs of clients to provide

professional technical services and participation, to meet the new

demands...

Established in 2006, Tech Plus Precision has upheld this

principle as the company’s policies and objectives to research, develop,

and design the Machine. Our main products are high speed glass engraving machines & engraving milling Machine, CNC Drilling Machine,

double column hi-speed machining center, double column integrate

machining center, etc. With its dedicated employees, the company was

awarded CE Certification in 2007 and the Certification of Tool Rest

Structure Design in 2008, the same year it developed the machining

center spindle shift mechanism, and the vacuum device for the processing

Machine was designed in 2009. We firmly believe that the

integrity of management, for all the needs of clients to provide

professional technical services and participation, to meet the new

demands...* Company Link * Company Profile * Company Video * View All Items

10. JIH-I Machinery Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan Manufacturers & Suppliers )

Jih-I Machinery Co., Ltd. established in 1971, specialized in

the design and manufacture of woodworking machinery. Our products

including cut-off saw, CNC Drilling Machine, CNC machining center, angle cutting and jointing Machine, panel saw, punching Machine, boring and milling Machine

and so on. In order to growing constantly, Jih-I spent a lot of time

and money developing new technology and products. In recent years, Jih-I

also has devoted itself to the manufacture of non-ferrous metal

machining equipment. Based on their concept of continual research and

development, they continuously develop new products to meet industrial

demands. Each Jih-I Machine is designed to reduce production

costs while upgrading working efficiency for the customers. Welcome to

visit our website for more details....

Jih-I Machinery Co., Ltd. established in 1971, specialized in

the design and manufacture of woodworking machinery. Our products

including cut-off saw, CNC Drilling Machine, CNC machining center, angle cutting and jointing Machine, panel saw, punching Machine, boring and milling Machine

and so on. In order to growing constantly, Jih-I spent a lot of time

and money developing new technology and products. In recent years, Jih-I

also has devoted itself to the manufacture of non-ferrous metal

machining equipment. Based on their concept of continual research and

development, they continuously develop new products to meet industrial

demands. Each Jih-I Machine is designed to reduce production

costs while upgrading working efficiency for the customers. Welcome to

visit our website for more details....* Company Link * Company Profile * Company Video * View All Items

11. Shenzhen Jianfeng Hardware Factory : CNC Drilling Machines

( Origin : Mainland China Manufacturer & Supplier )

Jianfeng Precision Hardware Manufacturer is an ISO 9001:2000

certified manufacturer for precision metal and plastic components to

customized specification with casting machining, milling, Drilling,

grinding, turning and stamping of different fininshing. We have a team

of customized solution for your precision components project as we have

our own casting facility, machining workshop and other metal processing

equipment like stamping, coiling etc. Our products were widely employed

in toy, electronics, telecommunication, medical equipment, aerospace

industrial, automotive, household, fire detection system etc. We are

driving with our AIMS--effective cost quality products, on-time

delivery, timely and effecient communication. Please contact us with

your CNC Drilling Machine requirements.

Jianfeng Precision Hardware Manufacturer is an ISO 9001:2000

certified manufacturer for precision metal and plastic components to

customized specification with casting machining, milling, Drilling,

grinding, turning and stamping of different fininshing. We have a team

of customized solution for your precision components project as we have

our own casting facility, machining workshop and other metal processing

equipment like stamping, coiling etc. Our products were widely employed

in toy, electronics, telecommunication, medical equipment, aerospace

industrial, automotive, household, fire detection system etc. We are

driving with our AIMS--effective cost quality products, on-time

delivery, timely and effecient communication. Please contact us with

your CNC Drilling Machine requirements.* Company Link * Company Profile * View All Items

12. Hanhsin Precision Industrial Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan Manufacturers & Suppliers ) Taiwan CNC Drilling Machine

manufacturer & supplier. Hanhsin Precision Industrial Co.,Ltd. was

established in 1996 and is a professional manufacturer. Our factory

incorporates the very latest in hi-tech machinery and testing equipment.

A reputable OEM manufacturer and professional fastener manufacturers,

Hanhsin Precision Industrial, continues to improve on product quality

and assure that each product exceeds the performance and reliability

standards expected by customers worldwide. Customers are assured of

receiving the most innovative and highest quality professional fastener

in the industry. Please do not hesitance to contact us now.

Taiwan CNC Drilling Machine

manufacturer & supplier. Hanhsin Precision Industrial Co.,Ltd. was

established in 1996 and is a professional manufacturer. Our factory

incorporates the very latest in hi-tech machinery and testing equipment.

A reputable OEM manufacturer and professional fastener manufacturers,

Hanhsin Precision Industrial, continues to improve on product quality

and assure that each product exceeds the performance and reliability

standards expected by customers worldwide. Customers are assured of

receiving the most innovative and highest quality professional fastener

in the industry. Please do not hesitance to contact us now.* Company Link * Company Profile * View All Items

13. Buildwell Industrial Co., Ltd. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier ) Buildwell Industrial Co., Ltd. was established in 1987 and specializes in manufacturing high precision drill chucks, CNC Drilling Machine, N.C. tooling for Machine centers as well as accessories for milling Machine, and grinding machines. We are one of the leading manufacturers and exporters in Taiwan supplying CNC Drilling Machine. In order to cope with ever-increasing demand in CNC Drilling Machine,

we have spared no efforts in upgrading our products through constant

research and development with innovative designs. Our products are

designed to meet the highest engineering standards. Total quality

control system is being implentmented so as to ensure reliable quality

products. Our products have successfully penetrated the world market.

For a reliable quality tool supplier and partner, our...

Buildwell Industrial Co., Ltd. was established in 1987 and specializes in manufacturing high precision drill chucks, CNC Drilling Machine, N.C. tooling for Machine centers as well as accessories for milling Machine, and grinding machines. We are one of the leading manufacturers and exporters in Taiwan supplying CNC Drilling Machine. In order to cope with ever-increasing demand in CNC Drilling Machine,

we have spared no efforts in upgrading our products through constant

research and development with innovative designs. Our products are

designed to meet the highest engineering standards. Total quality

control system is being implentmented so as to ensure reliable quality

products. Our products have successfully penetrated the world market.

For a reliable quality tool supplier and partner, our...* Company Link * Company Profile * View All Items

14. Michaellin Tools Mfg. Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan Manufacturers & Suppliers ) Michaellin Tools Mfg. Co., Ltd. was established to develop and manufacture CNC Drilling Machine.

Mr. Michael C. T. Lin, the owner of this company, has over 20 years

experience specializing in the research and development in CNC Drilling Machine.

We have successfully promoted our products in Hong Kong, South East

Asia, the United States and Europe. To comply with trends in

modernization and computerization in the market place, our R & D

department has devoted their efforts in researching CNC

computerized engraving machinery since 1987. In the future, we will

continue to devote our efforts to producing and supplying our customers

with highly refined machinery. Your comments, suggestions and inquiries

are most welcome.

Michaellin Tools Mfg. Co., Ltd. was established to develop and manufacture CNC Drilling Machine.

Mr. Michael C. T. Lin, the owner of this company, has over 20 years

experience specializing in the research and development in CNC Drilling Machine.

We have successfully promoted our products in Hong Kong, South East

Asia, the United States and Europe. To comply with trends in

modernization and computerization in the market place, our R & D

department has devoted their efforts in researching CNC

computerized engraving machinery since 1987. In the future, we will

continue to devote our efforts to producing and supplying our customers

with highly refined machinery. Your comments, suggestions and inquiries

are most welcome.* Company Link * Company Profile * View All Items

15. 7-Leaders Corp. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier )

Welcome to visit 7-Leaders, a specialized Tungsten Carbide Cutting Tools manufacturer. Our CNC Drilling Machine

products are widely used in many industries, such as automobile,

aerospace, machinery, electronic and mould & die and so on. Our

product with trade mark "7 Leaders" is not only well-known in Taiwan,

but also one of the leading brand in the market. We've built up the

fabrication facilities by "WALTER" CNC Grinding Machines which

supports us for non-stop automated Production 24 hours a day, 365 days a

year. Furthermore, we are equipped with WALTER "Helicheck" inspection

system to inspect even tools with diameter less than 0.1mm strictly. Due

to our latest grinding technology and innovative tool designed, we have

a great reputation in the global CNC Drilling Machine market. Feel free...

Welcome to visit 7-Leaders, a specialized Tungsten Carbide Cutting Tools manufacturer. Our CNC Drilling Machine

products are widely used in many industries, such as automobile,

aerospace, machinery, electronic and mould & die and so on. Our

product with trade mark "7 Leaders" is not only well-known in Taiwan,

but also one of the leading brand in the market. We've built up the

fabrication facilities by "WALTER" CNC Grinding Machines which

supports us for non-stop automated Production 24 hours a day, 365 days a

year. Furthermore, we are equipped with WALTER "Helicheck" inspection

system to inspect even tools with diameter less than 0.1mm strictly. Due

to our latest grinding technology and innovative tool designed, we have

a great reputation in the global CNC Drilling Machine market. Feel free...* Company Link * Company Profile * Company Video * View All Items

16. Topist Enterprise Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan Manufacturers & Suppliers ) Topist Enterprise Co., Ltd. is an international trading company. We specialize in widely range of CNC machined parts, CNC Drilling Machine,

assorted hardware part, chipboard screw, window screw, spring washers,

sintered product, roofing and carriage bolt, T-nut, thread forming

screw, micro screw, particle board screw, dowel screw, cars screw,

metric Machine screw, masonry screw, etc. Topist has

established since November year 1989 and qualified the ISO 9001:2000

since May year 1999. The customer widely spread in Asia, Europe,

American Continental, Pacific Ocean area and so on. There is an old

saying " a small soldier makes great merits" in China, what does it mean

is exactly screw. We perform our job according to the spirit of the old

saying to create the most value for the whole society.

Topist Enterprise Co., Ltd. is an international trading company. We specialize in widely range of CNC machined parts, CNC Drilling Machine,

assorted hardware part, chipboard screw, window screw, spring washers,

sintered product, roofing and carriage bolt, T-nut, thread forming

screw, micro screw, particle board screw, dowel screw, cars screw,

metric Machine screw, masonry screw, etc. Topist has

established since November year 1989 and qualified the ISO 9001:2000

since May year 1999. The customer widely spread in Asia, Europe,

American Continental, Pacific Ocean area and so on. There is an old

saying " a small soldier makes great merits" in China, what does it mean

is exactly screw. We perform our job according to the spirit of the old

saying to create the most value for the whole society.* Company Link * Company Profile * View All Items

17. JARNG YEONG ENTERPRISE CO., LTD. : CNC Drilling Machines

( Origin : Taiwan Manufacturer & Supplier ) JARNG YEONG is a specialized high-precision automatic lathe and CNC Drilling Machine

machinery manufacturer, supplier and exporter since 1978. We

consistency and constantly updated state-of-the-art technology and

facility to fulfill customers’ CNC Drilling Machine

needs. In 1990, we developed our first automatic lathe and received

positive responses from customers. We took out the CE certification of

automatic lathe and CNC lathe, exported to EU countries in

2004. In order to meet the dynamic industry needs, we have expanded our

factory to 7000㎡, and established the turning & milling combined Machine

R&D Center. Today we can provide over 500 lathe machines per year.

We have a good reputation and positive responses from the market. If you

need further information about our CNC Drilling Machine...

JARNG YEONG is a specialized high-precision automatic lathe and CNC Drilling Machine

machinery manufacturer, supplier and exporter since 1978. We

consistency and constantly updated state-of-the-art technology and

facility to fulfill customers’ CNC Drilling Machine

needs. In 1990, we developed our first automatic lathe and received

positive responses from customers. We took out the CE certification of

automatic lathe and CNC lathe, exported to EU countries in

2004. In order to meet the dynamic industry needs, we have expanded our

factory to 7000㎡, and established the turning & milling combined Machine

R&D Center. Today we can provide over 500 lathe machines per year.

We have a good reputation and positive responses from the market. If you

need further information about our CNC Drilling Machine...* Company Link * Company Profile * View All Items

18. Victor Taichung Machinery Works Co., Ltd. : CNC Drilling Machine

( Origin : Taiwan & Mainland China Manufacturers & Suppliers )

Founded in 1954, Victor Taichung Machinery Works Co., Ltd.

started with making conventional lathes in Taiwan and now steadily

supplies CNC machining centers and CNC Drilling Machine

by devoting our management to non-stop R&D and innovations. All

products are marketed globally under the brand names VICTOR or FORTUNE

which highlight our strong position as the leading manufacturer in

Taiwan. Insisting on "Technology Innovations and Quality Superiority",

we're continuously devoted to developing new generation of CNC Drilling Machine.

To ensure marketing for our products, we've invested considerably in

setting up a global distribution network. To strive for perpetual

development and technological innovations, we will keep on manufacturing

modern CNC Drilling Machine with greater value added and...

Founded in 1954, Victor Taichung Machinery Works Co., Ltd.

started with making conventional lathes in Taiwan and now steadily

supplies CNC machining centers and CNC Drilling Machine

by devoting our management to non-stop R&D and innovations. All

products are marketed globally under the brand names VICTOR or FORTUNE

which highlight our strong position as the leading manufacturer in

Taiwan. Insisting on "Technology Innovations and Quality Superiority",

we're continuously devoted to developing new generation of CNC Drilling Machine.

To ensure marketing for our products, we've invested considerably in

setting up a global distribution network. To strive for perpetual

development and technological innovations, we will keep on manufacturing

modern CNC Drilling Machine with greater value added and...* Company Link * Company Profile * Company Video * View All Items

New CNC Drilling Machine Products :

CNC Swiss-Type Lathes

CNC Drilling Tapping Centers

Gun Drill Machines

Milling Machines

Horizontal Boring And Milling ...

OCT-0035 Portable Drilling EDM ...

Hydraulic Automatic Drilling ...

Machine And Turning Parts

Horizontal Multiple Spindle ...

Drilling Machines

Automatic Loading Bicycle Axis ...

CNC Automatic Drilling Machines

Portal Milling Machine

NC Knee And Column Milling ...

NC Knee And Column Milling ...

Milling Machines

Drilling Machines

Bed Type Vertical Boring And ...

Pneumatic Automatic Drilling ...

Radial Manual Feed Drilling ...

Both

DCT0020 and DCT0040 are utilized in building in the following

CNC Drilling and Carving machines.

A

complete CNC solution is also developed in this project. Significantly,

both linear and arc interpolation functions are integrated with DSP to

enhance computational capability.

|

Wholesale Suppliers & Factory Price Contact Global Exporters Directly! · www.Alibaba.com

| Computer Numerical Control (CNC) Drilling |

|

| Computer Numerical Control (CNC) Drilling is commonly implemented

for mass production. The drilling machine, however, is often a

multi-function machining center that also mills and sometimes turns.

The largest time sink for CNC drilling is with tool changes, so for

speed, variation of hole diameters should be minimized. The fastest

machines for drilling varying hole sizes have multiple spindles in

turrets with drills of varying diameters already mounted for drilling.

The appropriate drill is brought into position through movement of the

turret, so that bits do not need to be removed and replaced. A

turret-type CNC drilling machine is shown below. A variety of semi-automated drilling machines are also used. An example is a simple drill press which, on command, drills a hole of a set depth into a part set up beneath it. In order to be cost-effective, the appropriate type of CNC drilling machine needs to be applied to a particular part geometry. For low-volume jobs, manual or semi-automated drilling may suffice. For hole patterns with large differences in sizes and high volume, a geared head is most appropriate. If holes are close to each other and high throughput is desired, a gearless head can locate spindles close together so that the hole pattern can be completed in one pass. For further reference for CNC processes, please refer to the CNC, metal forming section.

|

The Haas DT-1 is a compact, high-speed drill and tap machine with full milling capabilities. The machine has a 20" x 16" x 15.5" (xyz) work cube and a 26" x 15" T-slot table. A powerful BT30 taper inline direct-drive spindle provides 12,000 rpm, and allows rigid tapping at speeds to 5000 rpm. A high-speed, 20-pocket tool changer swaps tools quickly, while 2400 ipm rapids and high accelerations combine to shorten cycle times and reduce non-cutting time.

Specifications

Benefits

Applications

|

Application Data (tool description for CAM software)

|

CM404-100B-001SET Carving Bit Set |

|

|

4-flute premium tool |

||||

| ||||||||||||||||||||||||||||||||||||||||||||

Friday, 21 September 2012

CNC drilling machine - FINISHED!

With the new path finding routines in our CNC drilling software, and

changes to the firmware to allow the user to manually jog the drill head

up and down to get more precise alignment during initial set-up, we're

finally happy to say that our cheapo CNC drilling machine is finally

complete.

Or at least, complete to a state that we're happy to release for anyone else to have a go at making their own.

The last little part of the test was making sure that the machine could drill a PCB even when placed on the cutting bed at an angle. Here's a video showing exactly that:

The drilling is accurate enough for us now (there's still a little bit

of play in the x-axis, but we seem to have done enough to remove/reduce

any play in the y axis, even when the bed still needs to travel

up-and-down in order to correct for the board being at an angle)

Here's the final board, as drilled in the video:

The holes on the bottom-right-hand edge may not be absolutely bang on, but they're good enough to make the board usable, and are about as accurate as you could get by drilling the board by hand. The photo seems to emphasise the amount of drift - it's probably less than 0.5mm away from the centre of the hole.

Having successfully completed a cnc drill test, we put the machine away!

We reckon our machine fulfills all the criteria set in the CNC drill challenge.

It's been a long (and sometimes painful) journey, but it feels great to finally complete a project, not just to a point where it's working, but to be able to compare it to a list of criteria drawn up at the start, and to be able to tick every one off the list!

Along the way we were introduced to brushless motors and their servo-protocol control boards, created our own stepper motor control boards and our own USB-based protocol for moving them, and proved that rack-and-pinion gearing can be used just as successfully for CNCs as belt drives and leadscrews.

If we were to do the whole thing again?

Probably it'd look pretty similar. Maybe instead of a travelled bed-on-wheels we might use rails (similar to the x-axis) because there is a lot of play in the y-axis. But then again maybe not?

Any improvements?

Of course. Better stepper motors would be a great start. When energised, a stepper motor should have no movement in it at all - our steppers have 1mm-2mm of play because of the internal gearing. But then again, this does give us simple movement commands - no messing about with micro-stepping or any of that tricky stuff! We love the simplicity of the rack-and-pinion approach: belt-drives and leadscrews may be more popular, but we reckon we'd stick with ours.

The custom software is enough to make the device usable, but the protocol for sending x- and y- axis values is so simple that allow anyone else can write their own controller software. The latest firmware not only allows you to set a the number of steps to move in both x- and y- axes, but you can also now provide a "ratio" (for every three steps in x, move one in y for example). This means that if a vector line is broken down into enough parts, the machine could be modified to do simple milling - an idea that Justin from BuildBrighton is already working on!

Or at least, complete to a state that we're happy to release for anyone else to have a go at making their own.

The last little part of the test was making sure that the machine could drill a PCB even when placed on the cutting bed at an angle. Here's a video showing exactly that:

Here's the final board, as drilled in the video:

The holes on the bottom-right-hand edge may not be absolutely bang on, but they're good enough to make the board usable, and are about as accurate as you could get by drilling the board by hand. The photo seems to emphasise the amount of drift - it's probably less than 0.5mm away from the centre of the hole.

Having successfully completed a cnc drill test, we put the machine away!

We reckon our machine fulfills all the criteria set in the CNC drill challenge.

- You can load NC compatible drill files to operate the machine

- It cost less than £50 to build, completely from scratch with new (no salvaged) parts

- It's accurate to within 0.5mm (despite the dodgy cheapo stepper motors)

- The footprint is less than a sheet of A4 (in storage mode, it's about 210mm x 160mm)

It's been a long (and sometimes painful) journey, but it feels great to finally complete a project, not just to a point where it's working, but to be able to compare it to a list of criteria drawn up at the start, and to be able to tick every one off the list!

Along the way we were introduced to brushless motors and their servo-protocol control boards, created our own stepper motor control boards and our own USB-based protocol for moving them, and proved that rack-and-pinion gearing can be used just as successfully for CNCs as belt drives and leadscrews.

If we were to do the whole thing again?

Probably it'd look pretty similar. Maybe instead of a travelled bed-on-wheels we might use rails (similar to the x-axis) because there is a lot of play in the y-axis. But then again maybe not?

Any improvements?

Of course. Better stepper motors would be a great start. When energised, a stepper motor should have no movement in it at all - our steppers have 1mm-2mm of play because of the internal gearing. But then again, this does give us simple movement commands - no messing about with micro-stepping or any of that tricky stuff! We love the simplicity of the rack-and-pinion approach: belt-drives and leadscrews may be more popular, but we reckon we'd stick with ours.

The custom software is enough to make the device usable, but the protocol for sending x- and y- axis values is so simple that allow anyone else can write their own controller software. The latest firmware not only allows you to set a the number of steps to move in both x- and y- axes, but you can also now provide a "ratio" (for every three steps in x, move one in y for example). This means that if a vector line is broken down into enough parts, the machine could be modified to do simple milling - an idea that Justin from BuildBrighton is already working on!

| China (mainland) | Full catalog: 104 products

CNC Drilling Machine Micro CNC Drilling Machine, Safe and Reliable

CNC Drilling Machine Micro CNC Drilling Machine, Safe and Reliable

Chengdu Vista CNC Manufacture Co. Ltd

| China (mainland)

| Full catalog: 24 products

CNC Drilling Machine CNC Drilling Machine with Servo Sliding Power Head

CNC Drilling Machine CNC Drilling Machine with Servo Sliding Power Head

Jinan Tri-tiger Technology Development Co. Ltd

| China (mainland)

| Full catalog: 30 products

CNC Drilling Machine Three-dimensional CNC Drilling Machine for H-beams, with 30kW Installation Power

Min. Order: 1 to 99 Unit

CNC Drilling Machine Three-dimensional CNC Drilling Machine for H-beams, with 30kW Installation Power

Min. Order: 1 to 99 Unit

Liuzhou Biaohuang Import & Export Co. Ltd

| China (mainland)

| Full catalog: 30 products

CNC Machine Gantry Frame CNC Drilling Machine for Steel Plate Fixed Connection, with 40 to 2,500rpm Speed

Min. Order: 1 to 99 Unit

CNC Machine Gantry Frame CNC Drilling Machine for Steel Plate Fixed Connection, with 40 to 2,500rpm Speed

Min. Order: 1 to 99 Unit

Changshu Jingcheng Aluminum Co. Ltd

8 senior engineers with over 10 years' experience each

| China (mainland)

| Full catalog: 298 products | News/Research

Alloy Extruded Products Alloy Extruded Products with Cutting, Drilling, Punching and CNC Machine Deep Process

Min. Order: 500 to 999 Kilogram

Alloy Extruded Products Alloy Extruded Products with Cutting, Drilling, Punching and CNC Machine Deep Process

Min. Order: 500 to 999 Kilogram

YI XIN PRECISION METAL & PLASTIC LTD

CNC machining services trusted by Celestica, Porticos and other big-name buyers

| China (mainland)

| Full catalog: 300 products

Screw High-precision CNC Self Drilling Threaded Screw, Made of Aluminum, ODM/OEM Orders are Welcome

Min. Order: 1 to 99 Pieces

Screw High-precision CNC Self Drilling Threaded Screw, Made of Aluminum, ODM/OEM Orders are Welcome

Min. Order: 1 to 99 Pieces

Shenyang Bright Machinery Co.Ltd

Our radial drilling processing ranges from diameters of 25 to 125mm

| China (mainland)

| Full catalog: 112 products | News/Research

Drilling and Tapping Center Machine Center TC Series High-speed Drilling and Tapping Center with 650 x 420mm Worktable Size

Min. Order: 1 to 99 Set

Drilling and Tapping Center Machine Center TC Series High-speed Drilling and Tapping Center with 650 x 420mm Worktable Size

Min. Order: 1 to 99 Set

Shenzhen Zhouyu Intelligent Technology Co. Ltd

| China (mainland)

| Full catalog: 30 products

CNC Machine CNC Milling and Drilling Machine with 10mm Drilling Capacity and 100rpm Minimum Speed

Min. Order: 1 to 99 Unit

CNC Machine CNC Milling and Drilling Machine with 10mm Drilling Capacity and 100rpm Minimum Speed

Min. Order: 1 to 99 Unit

Guangzhou Yitong NC Co. Ltd

| China (mainland)

| Full catalog: 30 products

Cnc 3-axis Drilling and Tufting Machine Cnc 3-axis Drilling and Tufting Machine with 2.0 to 6.0mm Drilling Hole Diameter

Min. Order: 1 to 99 Set

Cnc 3-axis Drilling and Tufting Machine Cnc 3-axis Drilling and Tufting Machine with 2.0 to 6.0mm Drilling Hole Diameter

Min. Order: 1 to 99 Set

Wuxi Pyramid General Machinery Co. Ltd

| China (mainland)

| Full catalog: 30 products

CNC Cutting/Drilling Machine CNC Cutting/Drilling Machine with Heavy-duty Steel Gantry Beams, Used in Electricity and Bridges

Min. Order: 1 to 99 Set

CNC Cutting/Drilling Machine CNC Cutting/Drilling Machine with Heavy-duty Steel Gantry Beams, Used in Electricity and Bridges

Min. Order: 1 to 99 Set

CNC Drilling Milling/Routing Machine Desktop Mini CNC Drilling Milling/Routing Machine with 0.01mm Processing Accuracy

Min. Order: 1 to 99 Unit

CNC Drilling Milling/Routing Machine Desktop Mini CNC Drilling Milling/Routing Machine with 0.01mm Processing Accuracy

Min. Order: 1 to 99 Unit

Hangzhou Datian CNC Machine Tool Co. Ltd

| China (mainland)

| Full catalog: 38 products

CNC Metal Drilling and Milling Machine CNC Metal Drilling and Milling Machine, with Syntec EZ4 Controller

Min. Order: 1 to 99 Set

CNC Metal Drilling and Milling Machine CNC Metal Drilling and Milling Machine, with Syntec EZ4 Controller

Min. Order: 1 to 99 Set

Chongqing Jr. Sun Technology Development Co. Ltd

| China (mainland)

| Full catalog: 28 products | News/Research

CNC Vertical Drilling Machine Center CNC Vertical Drilling Machine Center with Highly Efficient Processing

Min. Order: 1 to 99 Set

CNC Vertical Drilling Machine Center CNC Vertical Drilling Machine Center with Highly Efficient Processing

Min. Order: 1 to 99 Set

Beijing Hongxin Union Technology Co. Ltd

| China (mainland)

| Full catalog: 17 products

Machine Parts Parts for CNC Drilling, Milling and Tapping Machines

Min. Order: 1 to 99 Pieces

Machine Parts Parts for CNC Drilling, Milling and Tapping Machines

Min. Order: 1 to 99 Pieces

CNC Engraver Machine Multifunction CNC Engraver Machine with 4.5kW Spindle, Cutting, Drilling, Engraving and Carving

Min. Order: 1 to 99 Set

CNC Engraver Machine Multifunction CNC Engraver Machine with 4.5kW Spindle, Cutting, Drilling, Engraving and Carving

Min. Order: 1 to 99 Set

Parado Enterprises Co. Ltd

| China (mainland)

| Full catalog: 30 products

CNC Machine Mini CNC Milling/Drilling/Router/Lathe Machine

CNC Machine Mini CNC Milling/Drilling/Router/Lathe Machine

D.Q Metal Products Co. Limited

| China (mainland)

| Full catalog: 30 products

CNC Machined Service CNC Machined Service with Drilling and Milling Machine Technique, Made of Brass, Customized Accepted

Min. Order: 2,000 to 2,999 Pieces

CNC Machined Service CNC Machined Service with Drilling and Milling Machine Technique, Made of Brass, Customized Accepted

Min. Order: 2,000 to 2,999 Pieces

Suzhou Easson Optoelectronics Co. Ltd

| China (mainland)

| Full catalog: 40 products

CNC Machine CNC Tapping and Drilling Machine with Low Inertia Spindle Design and High Speed

Min. Order: 1 to 99 Set

CNC Machine CNC Tapping and Drilling Machine with Low Inertia Spindle Design and High Speed

Min. Order: 1 to 99 Set

Dongguan Hongtai Industrial Co. Ltd

| China (mainland)

| Full catalog: 30 products

| China (mainland)

| Full catalog: 30 products

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Login or register for immediate download

Above CNC Drilling Machine suppliers include wholesale CNC Drilling

Machine, CNC Drilling Machine from China, India & Worldwide. Back to

top of the page for chinese CNC Drilling Machine.

Other Services

Other Services

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Shenzhen 1064 Laser Technology Co. Ltd

| China (mainland)

| Full catalog: 30 products

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Add to Basket

Items Per Page:

Products:

1 • 2

Download Hardware & DIY e-Magazine

Login or register for immediate download

- Discover new CNC Drilling Machine and other Hardware & DIY...

- Detailed information of verified CNC Drilling Machine suppliers

• More e-magazine titles available

• Subscribe for print copies - from US$5 a month

• Subscribe for print copies - from US$5 a month

• Also available on Global Sources Magazines iPad app

• Also available on Global Sources Magazines iPad app

Get Profiles of Verified Suppliers from China and Research on Market Trends

Can't find what you are looking for

Other categories or related manufacturers you may find interesting

Did you know?

More Information

What Every Buyer Needs to Know

Take a look at these "best of" materials from Global Sources.

You'll find the essential information you need for sourcing success. More

Other Services

Other Services

| China (mainland)

| Full catalog: 30 products

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Login or register for immediate download

Above CNC Drilling Machine suppliers include wholesale CNC Drilling

Machine, CNC Drilling Machine from China, India & Worldwide. Back to

top of the page for chinese CNC Drilling Machine.

Other Services

Other Services

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Drilling and Tapping machine High-speed Drilling and Tapping machine, Customized Requirements are Accepted

Min. Order: 1 to 99 Set

Shenzhen 1064 Laser Technology Co. Ltd

| China (mainland)

| Full catalog: 30 products

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Metal Laser Cutting Machine Metal Laser Cutting Machine, Applied for Cutting and Drilling the Carbon Steel

Min. Order: 1 to 99 Set

Add to Basket

Items Per Page:

Products:

1 • 2

Download Hardware & DIY e-Magazine

Login or register for immediate download

- Discover new CNC Drilling Machine and other Hardware & DIY...

- Detailed information of verified CNC Drilling Machine suppliers

• More e-magazine titles available

• Subscribe for print copies - from US$5 a month

• Subscribe for print copies - from US$5 a month

• Also available on Global Sources Magazines iPad app

• Also available on Global Sources Magazines iPad app

Get Profiles of Verified Suppliers from China and Research on Market Trends

Can't find what you are looking for

Other categories or related manufacturers you may find interesting

Did you know?

More Information

What Every Buyer Needs to Know

Take a look at these "best of" materials from Global Sources.

You'll find the essential information you need for sourcing success. More

Other Services

Other Services- - Setup and operate CNC Lathes or CNC Vertical/Horizontal Machining Centers to effectively ... alloys) is strongly desired - Mastercam CNC Programming experience is ideal -...from Billet Industries, Inc. - 14 days ago

-

Leader, CNC Turning Machine/Lathe

Bell Helicopter

- Grand Prairie, TXLeader Supervises a group of industrial machine operators in the production of a variety of precision, high-tolerance aviation components. Proven success in leading teams through...from Sologig - 15 days ago

-

CNC Machinist

has immediate openings for CNC machinists to program, setup, and operate 7 & 10 axis CNC S ... Style Lathes. Applicants with 5 years of CNC lathe and mill experience preferable, or...from Cutting Edge Machining Solutions, Inc. - 22 days ago

-

Numerical Control Machine Setup Op I(Job Code 246899BR)

- new

Lockheed Martin

- Lexington, KYNumerical Control Machine Set-up Operator I Security Clearance None Typical Minimums NA ... Experience with ProtoTrak knee and/or bed mills and ProtoTRAK lathe and Clausing Kondia ve...from Lockheed Martin - 1 day ago

-

CNC Milling&Lathe Setup Operator

Aerotek

- Upper Saddle River, NJopening for an experienced CNC Milling and Lathe machine set up operator. This ... experience with set-up, and operation of CNC Lathe machines and CNC Milling machines...from Sologig - 11 days ago

-

CNC Lathe Machinist

Superior Group

- East Aurora, NYResources is currently seeking three CNC Lathe Machinists for a location in East ... on all types of materials on a CNC lathe. *Performs set-ups and all other...from Sologig - 18 days ago

-

Manual Turret Lathe Operator

Lone Star Staffing

- Houston, TXManual Turret Lathe Operators Job Summary: Perform setups on CNC lathes in a fast-paced ... To apply for the Manual Turret Lathe Operator position, please click on the APPLY...from EmploymentGuide.com - 20 days ago

-

Production Workers CNC Set Up Machine Operators Tool Engineer

- new

Greenleaf Corporations

- Saegertown, PAProduction Workers CNC Set-Up/Machine Operators a ... Set-Up/Machine Operators/CNC- Set up and operate machining equipment for the production of...from Monster - 3 days ago

-

CNC Machine Operator

- new

Volt Information Sciences

- San Diego, CAWe are looking for CNC Mill and/or Lathe Machinists! We partner with local aerospace compa ... who are currently searching for Mill and or Lathe Machinists for temporary-to-hire...from Sologig - 1 day ago

-

CNC Operator

Stand-by Personnel

- Tulsa, OKCNC Operator - Claremore Run CNC machines mills or lathes 10.00-12.00 an hour with 1 shift diff..temp to perm..the company manufactures sucker rods. Apply for this position in...from EmploymentGuide.com - 6 days ago

Reply With Quote

Reply With Quote

-

-

to:

to:

DT-1

DT-1

The availability of inexpensive electronics has again changed the way speed control may be applied by allowing continuously variable motor speed from the maximum down to almost zero RPM in CNC big bore lathe . This had been tried in the late 19th century but was not found satisfactory at the time. Subsequent improvements in electric circuitry have made it viable again.